The Institution’s Innovation Council ( IIC) Al Ameen College in collaboration with IEDC conducted a field visit to KINFRA IT Park at Kalamassery on 06-07-2022.All the students members(30) and teacher coordinators reached the destination at 10 am .The FAB Lab have ZUND G3 L-2500 Digital Cutter, OMAX 5555 Waterjet Cutter, Mitsubishi MV1200-S Advance Type M800-Wire EDM, Trotec Speedy 400 Flex Laser Cutter, Form labs Form 3-3D Printer, Prusa i3 MK3S- 3D Printer, Sindoh 3DWOX 1- 3D Printer, Tormach 15L Slant PRO-CNC Lathe, DPM RX 2- Vertical Milling Machine, Injection Molding Machine, Artec Leo 3D Scanner,Shaper Tools- Origin,Lynx EVO Stereo Microscope etc.

All are Electronic devices to increase the working proficeincies.Our students got an awareness about each devices .Some of the important facts which arrest our memory includes The Zund an accurate high-speed gantry with a variety of available tools for cutting, plotting, creasing, scoring, milling, drawing, etc. A range of modules provide the capability to cut, score, crease and mill. Use cases include origami/kirigami for rapid cutting-and-folding of structures with tunable properties, two-sided milling for press fit furniture and cutting of carbon fibre fabric for composite layups. Sindoh 3DWOX 1- 3D Printer prints the part layer by layer by an additive method from a CAD data or 3D scanned data without human intervention with minimal or no wastage of material. This avoids the need for secondary operations and gives the final output with all features out of the 3D Printer. Prusa i3 MK3S- 3D Printer does the prints the part layer by layer by an additive method from a CAD data or 3D scanned data without human intervention with minimal or no wastage of material.

This avoids the need for secondary operations and gives the final output with all features out of the 3D Printer. Form labs Form 3-3D Printer includes the prints of the part layer by layer by an additive method from a CAD data or 3D scanned data without human intervention with minimal or no wastage of material. This avoids the need for secondary operations and gives the final output with all features out of the 3D Printer.

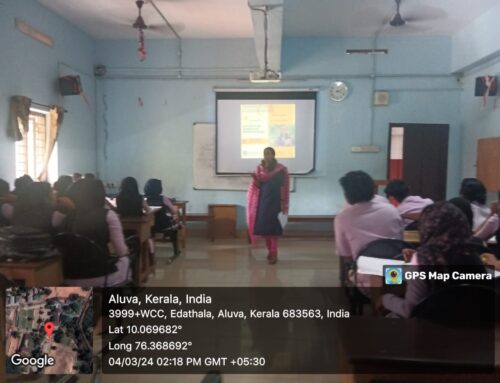

The programme was coordinated by Ms. Nisha Joseph, Ms. Renjini T N and Remya B Nair.

Leave A Comment